Equipment

Rack Processing Capabilities

Boschert CNC punching machine

Copper (max. thickness) ½”

Steel (max. thickness) ¼”

The machine is made for efficient punching of copper, steel another alloys.

Punching up to 4 m long (option up to 6 m) and a width of 15 mm up to 200 mm and a thickness from 3-15 mm

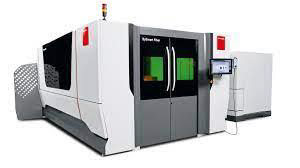

BySmart Fiber Laser

Outstanding cutting performance for high parts output and excellent cutting quality with thin to medium sheet metal

Wide range of applications. In addition to steel, stainless steel, and aluminum, non-ferrous metals can also be processed while maintaining excellent quality

Steel (max. sheet thickness) 30mm

Stainless steel (max. sheet thickness) 30 mm

Brass (max. sheet thickness) 15 mm

Copper (max. sheet thickness) 12 mm

Titanium (max. sheet thickness) 30 mm

Normal sheet size – 48” x 96”

Max sheet size – 60’ x 120”

Brake Press (U.S. Industrial Machinery) 88 tons – CU, AL, HRST, SS Anything up to 3/8HRST

Brake Press (Chicago)- Anything up to 1/2in HRST

Hydraulic Bender-bending up to 1/2in HRST

Metal bender– Creates uniform curved metal pieces

Sandblaster- Medium: Brown Aluminum Oxide. Room 9 x 9 x 17 ft

Bochert ECCO-LINE – Hole punching up to 3/8 Thick CRST

Unibend: Bending CRST, HRST, AL, Cu and Ti up to 1/2in thick and 3/4in tall. Accurate to +/- .1 Deg

Other Rack Processing (Dayton) Capabilities:

- Hole Tapper- Set up for tapping ¼-20 holes and 3/8-16 holes. Can tap anything with the proper bit.

- Band saws- Cutting for larger material.

- Wire bender-.0625 to .125in wire. SS or Ti.

- Rousselle #2G-Press10 – Kicker for Copper or HRST 1/4in max

- Rousselle #2K Press 2 – Dimple Machine up to 1/8in SS or TI.

- Bateman #20 – Press 34 Puts dips and sharp little kicks in material. SS and Ti. 1/16 to .090 material max

- Left- Rousselle #1A- Press 4 Max 1/8in material SS or Ti. Kicker.

- Right-Rousselle #0A-Press 11. Max 1/8in material SS or Ti. Kicker.

- Rousselle #2 Press 9 hole puncher max 1/4in Copper and HRST

- MIG Welding – HRST, CRST

- TIG Welding- SS, AL, Ti, Bronze

- Spot welders- Spot weld SS, Ti and Al.

- Soldering- solder pot 9in deep x 10in wide x 70in long

- Preheat, cure and Burnoff capabilities due to ovens.

- Plastisol tank for coating – 4ft wide x 7ft deep x 10 ft long.