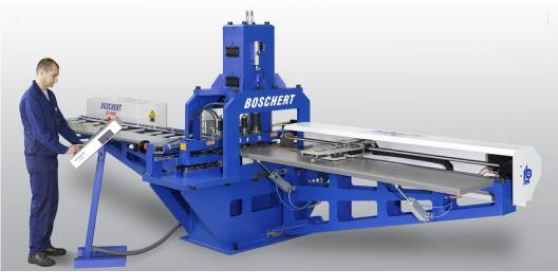

Boschert CNC punching machine

Copper (max. thickness) ½”

Steel (max. thickness) ¼”

The machine is made for efficient punching of copper, steel another alloys.

Punching up to 4 m long (option up to 6 m) and a width of 15 mm up to 200 mm and a thickness from 3-15 mm

BySmart Fiber Laser

Outstanding cutting performance for high parts output and excellent cutting quality with thin to medium sheet metal

Wide range of applications. In addition to steel, stainless steel, and aluminum, non-ferrous metals can also be processed while maintaining excellent quality

Steel (max. sheet thickness) 30mm

Stainless steel (max. sheet thickness) 30 mm

Brass (max. sheet thickness) 15 mm

Copper (max. sheet thickness) 12 mm

Titanium (max. sheet thickness) 30 mm

Normal sheet size – 48” x 96”

Max sheet size – 60’ x 120”

BambuLab X1C 3D Printer

- Build Volume (W×D×H) : 256 × 256 × 256 mm³

- Nozzle : 0.4 mm and 0.6mm Hardened Steel Included

- Supported Filament : PLA, PETG, TPU, ABS, ASA, PVA, PET Ideal for PA, PC, Carbon/ Glass Fiber Reinforced Polymer

Brake Press

(U.S. Industrial Machinery) 88 tons – CU, AL, HRST, SS Anything up to 3/8HRST

Brake Press (Chicago)

Anything up to 1/2in HRST

Hydraulic Bender

Has pins and can bend up to 1/2in HRST

Metal bender

Creates uniform curved metal pieces

Scotchman Iron Worker

Cuts anything to 1/2in steel to length

Sandblaster

Medium: Brown Aluminum Oxide.

Room 9 x 9 x 17 ft

Bochert ECCO-LINE

Hole punching up to 3/8 Thick CRST

Unibend

Bending CRST, HRST, AL, Cu and Ti up to 1/2in thick and 3/4in tall. Accurate to +/- .1 Deg