Rack has the capability to design, cut, form and weld a variety of metal products. Using steel, titanium or other substrates to make anything from material handling carts to one off prototype designs, we are your source. Tig and Mig Welding available. Our experienced team of professionals will make your next project successful and trouble-free.

Our BySmart Fiber Laser provides outstanding cutting performance for high parts output and excellent cutting quality with thin to medium sheet metal. Wide range of applications. In addition to steel, stainless steel, and aluminum, non-ferrous metals can also be processed in excellent quality

Steel (max. sheet thickness) 30mm

Stainless steel (max. sheet thickness) 30 mm

Brass (max. sheet thickness) 15 mm

Copper (max. sheet thickness) 12 mm

Titanium (max. sheet thickness) 30 mm

Normal sheet size – 48” x 96”

Max sheet size – 60’ x 120”

Copper (max. thickness) ½”

Steel (max. thickness) ¼”

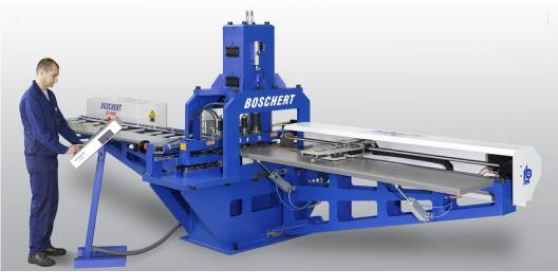

The machine is made for efficient punching of copper bars and is equipped with:

Punching of copper bars up to 4 m long (option up to 6 m) and with a wide of 15 mm up to 200 mm and a thickness from 3-15 mm

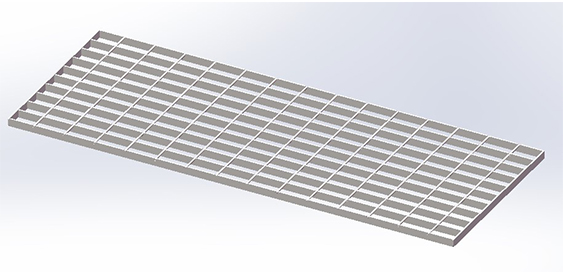

Custom industrial floor grating